We use cookies to enhance your browsing experience. If you are OK with this please click Opt-In. You can always remove your permission by clicking Opt-Out on the Privacy Policy page.

Segment wear

As a saw blade is used, wear occurs.

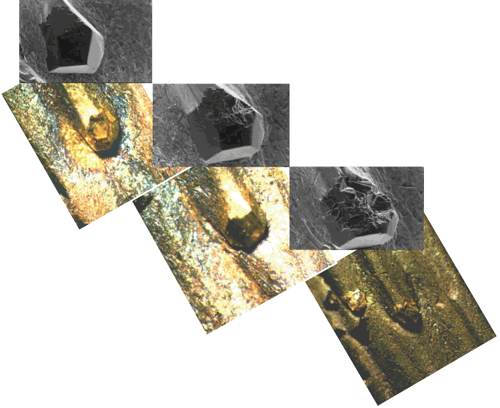

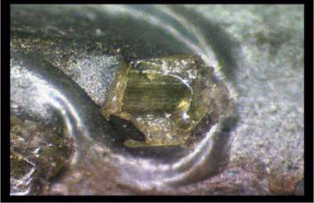

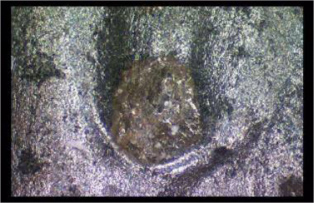

A diamond particle wear progression, is shown, where the stages are:

emerging

wearing

microfracturing

The black and white photographs are from a scanning electron microscope (SEM).

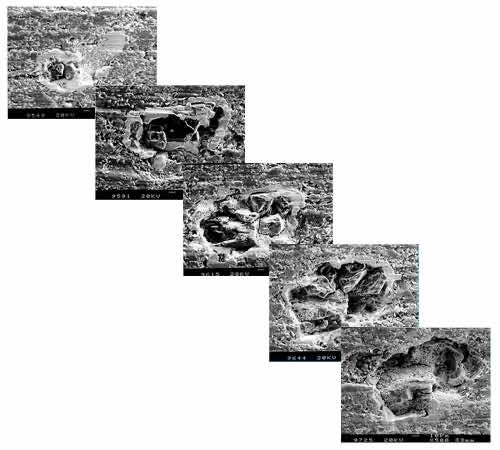

Diamond wear classification

A complete cycle of diamond wear can be classified as shown, where the progression of wear is top to bottom.

| Wear Stage | Photograph | Progression |

|---|---|---|

| Emerging |  | ⬇︎ |

| Wear flat |  | ⬇︎ |

| Wear flat & microfracture |  | ⬇︎ |

| Microfracture |  | ⬇︎ |

| Cleaved |  | ⬇︎ |

| Particle loss |  | ⬇︎ |

Segment wear analysis

Analysing worn saw blade segments allows comparisons to be made, for example saw blades on various granites (hard) and sandstone (abrasive).

Click on the data label to add / remove a data set.

Note that SMT has the expertise to advise on this type of analysis.

This wear progression can be compared to that of grinding grit.

Diamond for resin bond tools has a microchipping structure which ensures a degree of friability.

The wear progression of this type of diamond is shown:

emerging

microchipping

developed microchipping

advanced microchipping

particle loss

Free cutting

Large wear flat:

decreased free cutting

Multiple contact points:

increased free cutting