We use cookies to enhance your browsing experience. If you are OK with this please click Opt-In. You can always remove your permission by clicking Opt-Out on the Privacy Policy page.

PolyCrystalline Diamond (PCD)

Polycrystalline diamond (PCD) consists of micron diamond powders bonded together by sintering at high pressures and temperatures (at a temperature of approximately 1,500°C and a pressure of approximately 5GPa). The polycrystalline form is 'isotropic' - exhibiting uniform properties in all directions.

PCD is usually produced on a cemented carbide substrate which provides a source of metal catalyst to aide sintering (e.g. cobalt). Under extreme pressures and temperatures this cobalt infiltrates the layer of micron diamond powder causing neighbouring grains to sinter together. A small residue of cobalt makes the PCD tougher and conductive, so, PCD may be electric discharge machined. The tungsten carbide substrate also allows the brazing of PCD.

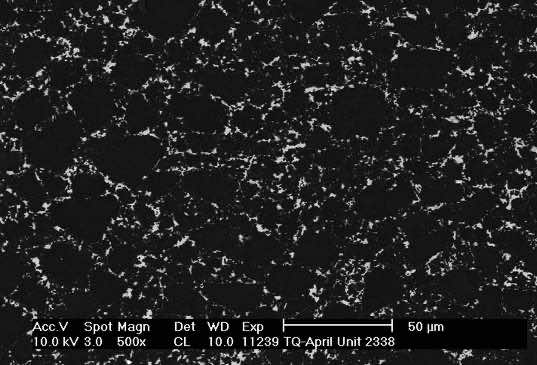

Polycrystalline diamond layer

In the Scanning Electron Micrograph above, diamond is black and the metallic binder is white.

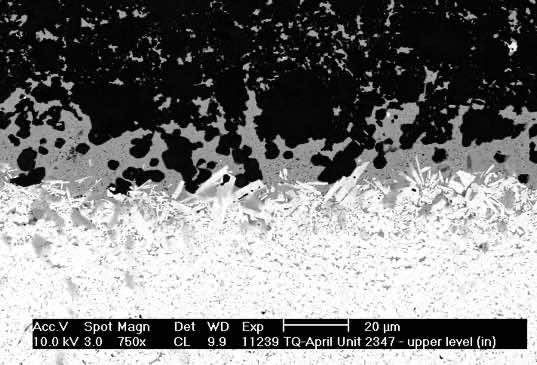

Interface

In the Scanning Electron Micrograph above, polycrystalline diamond is at the top and the cemented carbide substrate at the bottom.

Comparison of tool & workpiece hardness

Properties of cutting tool materials

Typical cutting parameters

Polycrystalline diamond (PCD) is available in several quality grades with varying grain size and cobalt content and has been used in the wood/composites industry for over 3 decades.

PCD tools are used extensively in automotive and aerospace industries. They are ideal for the machining of tough and abrasive aluminum alloys, high-abrasion materials such as carbon fibre and ceramics as well chipboard, MDF, particle board and HDF. High volume processes, tight tolerances and highly abrasive workpieces are ideal for PCD tooling.

| Workpiece Material | Cutting Speed (m/min) | Feed (mm/rev) | Depth of Cut (mm) |

|---|---|---|---|

| Aluminium | 600-1,000 | < 0.50 | < 4.0 |

| Al Alloy (Si 4 - 8%) | 100-2,500 | < 0.50 | < 4.0 |

| Al Alloy (Si 9 - 13%) | 100-1,500 | < 0.50 | < 3.0 |

| Al Alloy (Si >13%) | 100-1,000 | < 0.40 | < 2.5 |

| Al Alloy (Si >21%) | 50-200 | < 0.30 | < 2.0 |

| Brass & Bronze | 100-1,000 | < 0.50 | < 3.0 |

| Carbon Fiber Composite | 200-1,500 | < 0.30 | < 3.0 |

| Ceramics | 100-600 | < 0.50 | < 2.0 |

| Glass Fiber Reinforced Plastics | 100-800 | < 0.50 | < 5.0 |

| Metal Matrix Composites | 100-600 | < 0.50 | < 3.0 |

| Sintered Tungsten Carbide | 10-40 | < 0.30 | < 1.0 |

| Titanium Alloys | 50-200 | < 0.20 | < 2.0 |

| Wood (MDF) | 100-4,000 | < 0.50 | < 10.0 |

PCD processing

Tool production, using polycrystalline diamond, involves several techniques depending upon:

• the tool material and

• the tool application.

The processes involved in tool fabrication are: